Have you ever wished that you could build your own physical models from just a digital image, but just did not know where to start? Well, look no further, because you can now do just that right here on Trinity’s campus.

Thanks to the new 3-D printing technology recently acquired by the AT&T Center for Learning and Technology, the creative possibilities are endless.

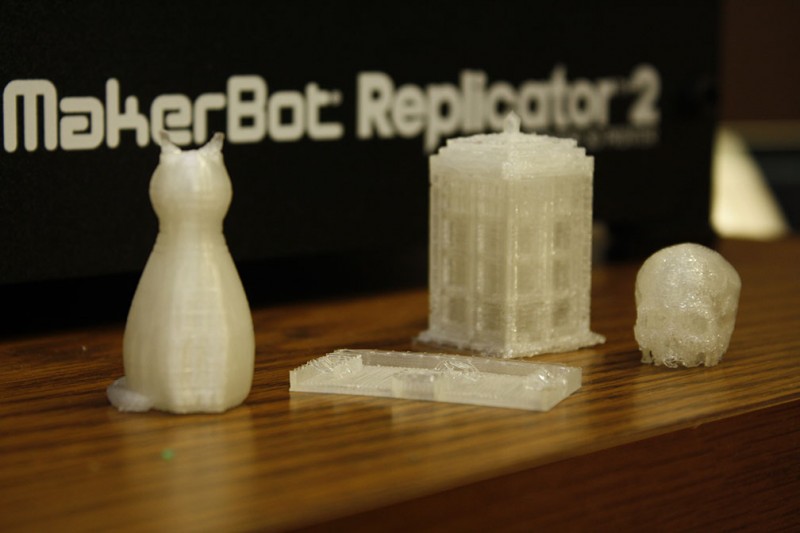

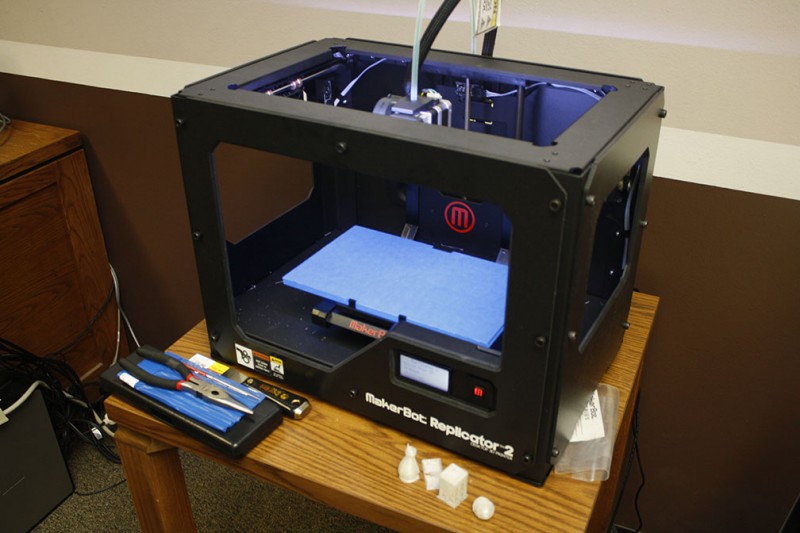

Known as the MakerBot Replicator 2, this 3-D printer, made by MakerBot Industries, is able to print at three levels: 300, 200 and 100 micron resolutions, which are also referred to as low, medium and high resolutions. The print surface has the general dimension of the build plate, and anything within that build plate can essentially be printed as vertically high as that plate is able to lift.

Coupled with a website dedicated to the sharing of user-created digital design files, called Thingiverse, even 3-D novices should have no trouble picking out a design they like and printing it out.

“Up until now, 3-D printers as industrial units have been very expensive and very large, requiring lots of material cost. The Replicator 2 represented the first time that a company had made an inexpensive, affordable and really good printer that really anyone can use. It just happened to be the right time for us to get it,” said Robert Chapman, director of the AT&T Center for Learning and Technology.

CLT purchased the printer back in November, but its arrival was delayed because of the effects of Hurricane Sandy in the Brooklyn area, which is where the company that manufactures the printers is located. Chapman is excited to see how Trinity students will use the printer for class assignments and individual projects.

“We want to make it available for faculty and students who would like to use it for coursework that they’re working on, ideas that they have that they want to prototype out, the general idea is that it represents affordable technology that has previously been quite unaffordable,” Chapman said.

One of the reasons the use of the MakerBot Replicator 2 will be so affordable is its relatively small scale Chapman said. Its affordability will also allow students from many different disciplines to make use of the new 3-D printer.

“We’re looking at everything from the humanities, where people are looking at ancient things as well as things that are very modern,” Chapman said.

Jack Leifer, associate professor of engineering science, heard about the printer through Michael Lawrence, who is with the Trinity Development office. According to Leifer, the engineering science department is also planning to purchase at least one 3-D printer for their new facilities in the Center for Sciences and Innovation. Leifer already has experience with 3-D printing technology from a first-year design class he taught at the University of Kentucky 10 years ago, so he has an idea of what works and what does not work for class projects.

“It is not practical to mandate use of a 3-D printer for a large class or set of assignments because of the high cost of materials and the amount of time and labor required to produce the parts. However, what the 3-D printer will be most useful for are design classes where certain groups need to make intricate parts that cannot be produced usinganother method,” Leifer said.

Sophomore Peter Steinbach can see 3-D printing being an effective tool for class instruction, especially in certain disciplines.

“I think that the printer could definitely be used for class assignments and projects, particularly in graphic design, engineering and theater. Professors would be able to create personalized demonstrations and models for lessons, and students would have a much more effective means of creating 3-D structures than they would if they were restricted to a 2-D screen,” Steinbach said.

While the capabilities of 3-D printing impress Steinbach, they also concern him with how far people who use the 3-D printer can go with their creations.

“What interests me most about the printer is actually related to Trinity’s moral position on making the device available to the student body and faculty,” Steinbach said. “With the ability to download models of a plethora of different objects from the Internet, what is to stop someone from printing a functioning gun or other harmful objects, let alone the litter that might be caused by someone with a credit card and a knack for creating trinkets?”

Under a list of available models that users can create, Thingiverse actually has a .44 magnum model ready to be downloaded and printed. Steinbach believes that rules need to be set for the printer to make sure that it is being used productively and for the right reasons.

“Trinity is going to have to make a formal printing policy in regards to the printer, and they will also need to make sure that access is either restricted or closely monitored, just to make sure that students don’t abuse it,” Steinbach said. “It will be excellent in terms of productivity; however, if it is prohibitively expensive, no one will use it, while if it is too cheap, it could become a source of a number of issues that might be better left alone.”

According to Chapman, CLT is still trying to figure out the accounting side of the printer.

“It’s one of those things where we’re always trying to make technology available, and it doesn’t make sense for us to price it or support it in such a way where it just sits unused. At the same time, there are material costs, so the material costs are where we’re thinking we’re going to try and kind of manage it,” Chapman said.

Currently, a spool of material sits behind the printer, and that material is fed into the printer when a printing job comes up. The spools of material generally weigh a kilogram, and the material costs about $47 per kilogram to purchase. In the end, things end up coming out to approximately $1.33 an ounce.

“The big thing for us is that it’s such a new type of thing that we’re going to be more liberal in how we express it with students, and then, as we see a need, we’re going to start sort of formalizing the processes for how we sort of manage that accounting,” Chapman said.

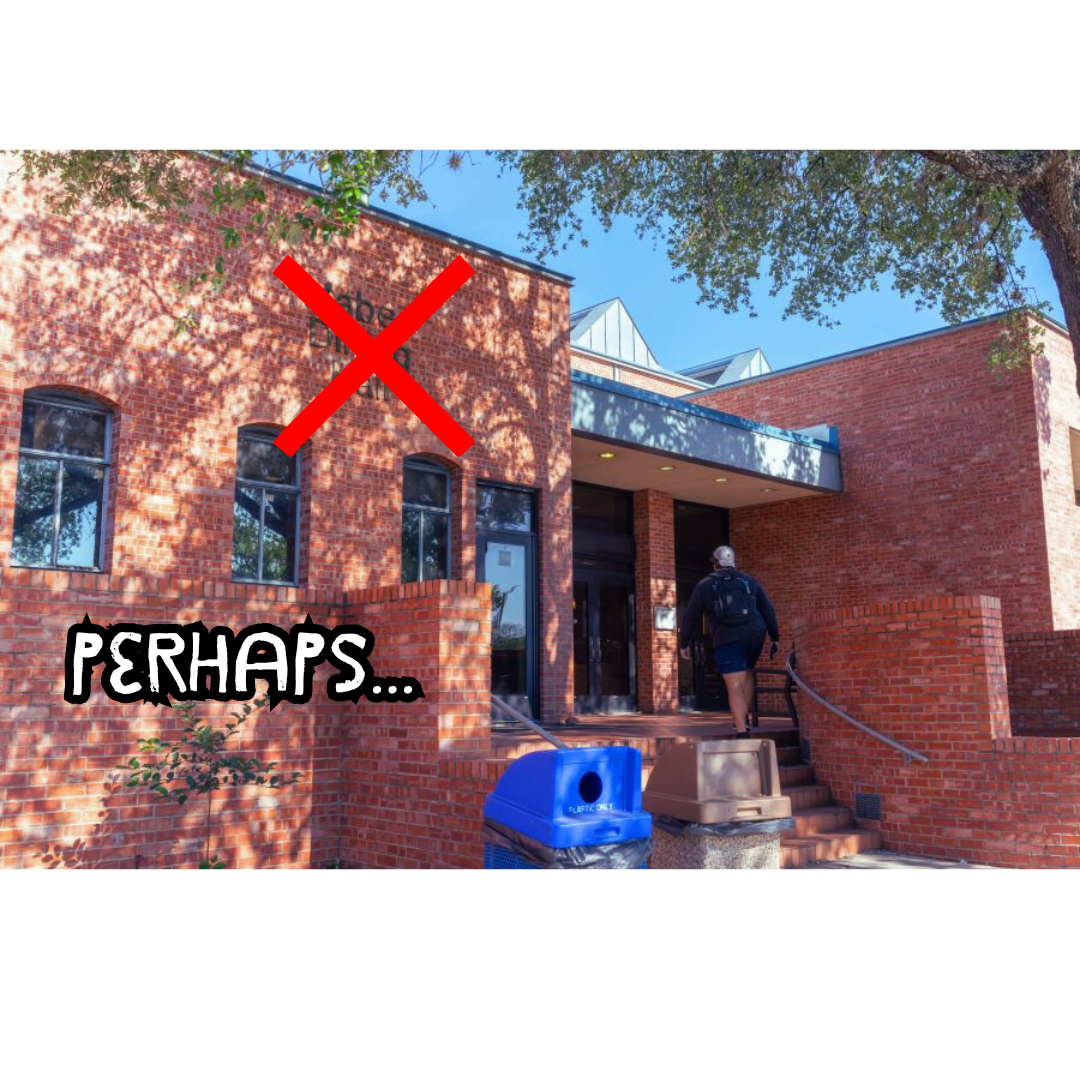

The MakerBot Replicator 2 3-D printer is located on the first floor of the library in the AT&T Center for Learning and Technology.

Students and professors interested in using the printer for projects are encouraged to contact CLT for more information.

Jeremy Keys • Feb 12, 2013 at 10:34 pm

Good article, very information.

Jeremy Keys • Feb 13, 2013 at 12:03 am

Also very informative…