Besides starting with the same letter, what do the words boobs and bees have in common with each other?

At Trinity University, plastic replicas have been made of both with the help of the school’s new 3-D printer.

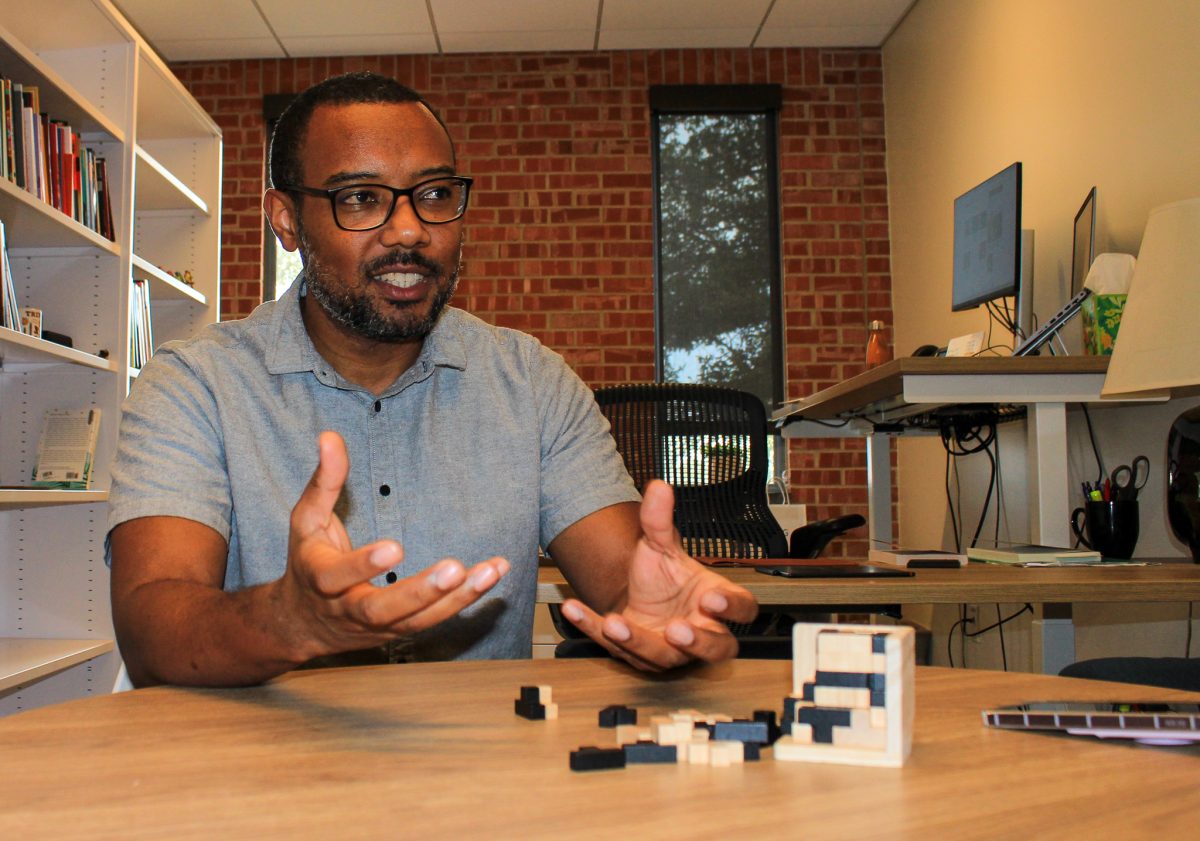

Installed at the beginning of the spring semester of 2013, the 3-D printer is located in the AT&T Center for Learning and Technology on the first floor of the library. Currently, printing is free for all students and faculty.

“We’ve basically told people that so long as you’re using it for your studies and the printing costs are not exorbitant, we’ll absorb the cost,” said Robert Chapman, director of the CLT. “People have been really nice about it.”

Last spring, senior Cade Bradshaw used the 3-D printer to construct his project about colony collapse disorder, specifically, how bees are interrelated to agriculture and human lives, for Jessica Halonen’s Advanced Drawing class.

“I was building my own hive on a panel of wood using beeswax, so I logged onto an online 3-D design software and I made a sculpture of a half-inch bee for my project for the class,” Bradshaw said.

“The printer is kind of like an extremely fancy hot glue gun. It crisscrosses strings of plastic filament back and forth to create a web and it builds on itself in the right formations.”

The printer is not only a benefit to studio art students. This past summer, Joshua Schwartz, assistant professor of engineering science, led a research team of four engineering students – Eric Schluter, Eric Kang, Yahe Zhou and Greg Walls – on a project to build and incorporate an imaging system into a bra that detects breast cancer. In order to make a form-fitting design, the team used the printer to create a 3-D model breast.

“The guys at CLT were all very amused that we were printing 3-D boobs, until they realized that it’s for a good cause,” Schwartz said. “We used the model that we printed to try different techniques of fitting our design onto that shape, which is much better than harassing people with a flexible circuit board.”

The research team has now settled on a design and is finishing up final touches before they send it out for fabrications.

Although using the printer sounds potentially quite complicated, the CLT staff is more than willing to help.

“We encourage anyone to come in and we’ll provide support and training,” Chapman said. “I consider it a good problem if I have to buy more 3-D printers.”

Between helping to demonstrate the importance of bees and creating a bra to detect breast cancer, the printer has already more than proved its worth.

“I think it challenges most of us to look outside the box a little more,” Bradshaw said. “It has a lot of applications, and you can fix almost anything with it. If you’re missing a part, or if you need a custom tool, you can design that. There’s great commentary on the machine itself on how our society is changing.”